Mud Construction: A Step-by-Step Guide

So many vacation rentals are popping up around you. How can you differentiate yourself from your competitors or even surpass them?

Yes! You can achieve this by creating something unique. If you want your vacation rental to stand out, consider using mud construction.

Mud construction is a type of building technique that involves using clay, silt (very fine sand), gravel, stones, and other natural materials to create walls, foundations, and other structural elements of a building. Mud as a building material is humanity’s oldest building material. It comes in a thousand different compositions and can be variously processed with many different applications. These applications of mud construction themselves have various names like rammed earth, soil blocks, mud bricks, or adobe.

Mud as a construction material

The composition and varying properties of mud depend on local conditions. Gravelly mountainous mud is more suitable for rammed earth - a type of mud construction - (that is if they have the required clay content), while riverside mud is often siltier and therefore less weather resistant and weaker in compression.

Like cement in concrete, clay acts as a binder for all larger particles in mud construction. Silt, sand and aggregates constitute the fillers in the mud.

Clay

Clay is fine grain particles of soil. It develops plasticity when wet but is hard, brittle and nonplastic when dried or fired.

Silt, Sand, and Gravel

Silt, Sand, and Gravel are simply aggregates that lack binding forces and are formed either from eroding stones, in which case they have sharp corners or by the movement of water, in which case they are rounded.

Organic Constituents

Soil dug from the surface of the earth (depth of less than 40cm) usually contains plant matter and humus (rotting plants) which is not good for mud construction. Under certain conditions, plant matter like straw can be added to mud construction, provided it is dry and there is no danger of later deterioration.

Water

Water activates the binding forces of the mud.

Preparing Mud for Construction

It is not always easy to produce building materials out of clayey soil for mud construction. Experience is required. The right preparation depends on the type of mud, its consistency, and its expected application.

Moist-crumbled earth with less clay and more sand content can be used immediately to build a rammed earth wall even as it is dug out.

Lumps of the earth with high clay content cannot be used as a building material. They must either be crushed or dissolved in water and thinned with sand.

Stabilization against water erosion

Mineral Stabilizers (Binders)

Cement

Cement acts as a stabiliser against water, especially in soils with low clay content. The higher the clay content, the more cement is needed to produce the same stabilising effect. Cement interferes with the binding force of the clay and therefore it is possible that the compressive strength of cement-stabilized soil is less than that of the same soil without cement.

As with concrete, the maximum water resistance of cement-stabilized soil block is reached after 28 days. These blocks must cure for at least seven days and should not dry out soon. If not protected against direct sun and wind, the blocks must be sprayed by water while curing.

Lime

The optimum lime content for mud construction differs and should be tested in advance in each case. If only a small amount of lime is added, the compressive strength may be lower than that of unstabilized mud.

Bitumen

Normally, bitumen is effective for mud construction with low clay content. The stabilising effect is more pronounced if the mixture is compressed. For that reason, the bitumen is either dissolved in water with an emulsifier such as naphtha, paraffin oil, or petroleum.

Animal Products

Animal products like blood, urine, manure, casein and animal glue have been used through the centuries to stabilise mud. In former times, oxblood was commonly used as a binding and stabilising agent.

Whey and urine are the most commonly used stabilisers for mud surfaces. If manure is used, it should be allowed to stand for one to four days in order to allow fermentation; the stabilisation effect is then considerably enhanced.

In India, traditional mud plaster (gobar plaster) has a high content of cow dung, which has been allowed to stand in a moist state for at least half a day. This mud construction technique is still in use.

Plant Products

Plant juices containing oily and latex and derived from plants such as sisal, agave, bananas and euphorbia here, usually in combination with lime, are used as a stabilising coating. Investigations show that a high degree of weather protection could be obtained for mud surfaces using double-boiled linseed oil. Several reports show that cooked starch and molasses can also be used to enhance stability. This effect is more pronounced if a little lime is also added.

Artificial Stabilizers

Synthetic resins, paraffin, synthetic waxes, and synthetic latex are all known to have a stabilising effect on mud. However, they are relatively expensive and are prone to ultraviolet degradation. These stabilisers should be tested before use. Silane, siloxane, silicones, silica ester, and acrylates all have water-repellent effects.

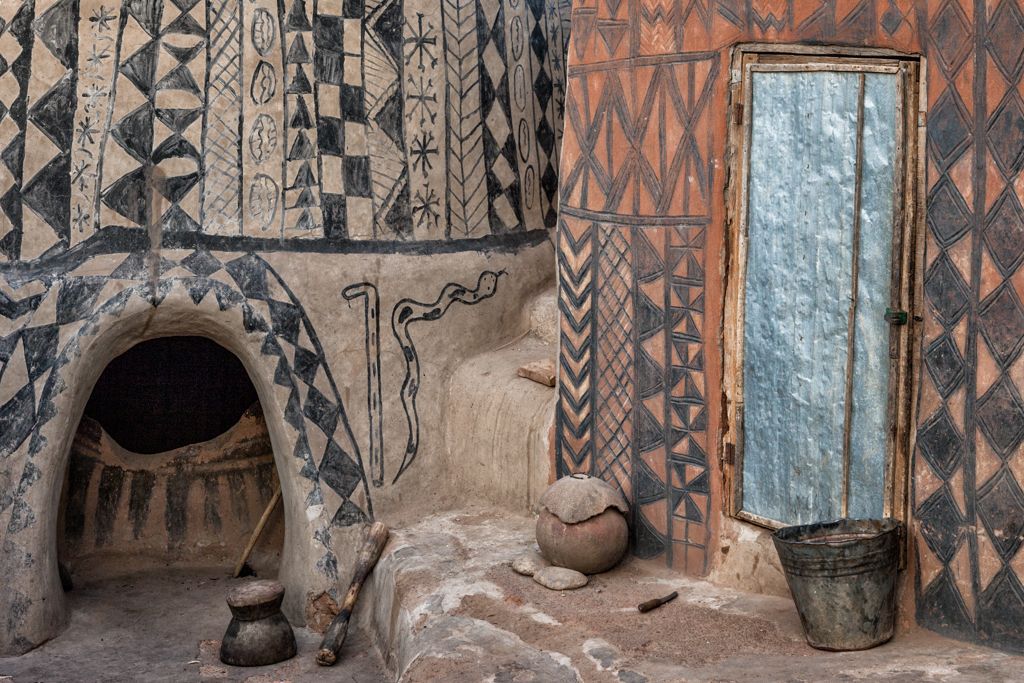

Mud huts covered in mud, cow dung, soil, pulverised rock, clay and chalk to produce elaborate geometric patterns on the facades of the houses via Photographer Louis Montrose

Building of Mud Houses

Mud Walls

Different techniques are used to build mud walls. To name a few,

Rammed Earth

Earthern blocks

Wet Mud Construction Techniques

Wet mud infill in skeleton structures

House of Earth and Stone finished in natural mud plaster via ArchDaily

MUD PLASTERS

Mud plasters consist mainly of sand and silt with only as much clay as is necessary for developing their adhesive and binding forces. It is difficult to determine the proportions of an ideal mud plaster, because not only the proportions of the clay, silt and sand also influence the mixture’s properties.

Other factors affecting the composition are the grain size distribution of the sand fraction itself, the water content, the type of clay, the method of preparation and the additives. In order to test the appropriateness of the mud plaster, samples with varied compositions should be tested. If the surface is rough enough, then mud plasters stick well not only to mud surfaces but also to those made of brick, concrete and stone.

MUD FLOORS

Floors can be filled with mud to increase fire resistance, sound insulation and thermal insulation as well.

MUD COVERED ROOF

In dry climate zones, flat roofs covered with earth have been in use for centuries in traditional rural mud construction. One of the greatest challenges when building in a developing country is to produce successful, weather-resistant mud roofs that might prove durable in rainy seasons. The cost of such a roof structure is usually 25% to 30% of the total building cost.

MUD BATHROOMS

The fact that a mud-finished bathroom is more hygienic than a tiled bathroom surprises many. Both experiences over several years with bathrooms having mud walls and scientific investigation regarding the absorptive and desorptive behaviour of mud have, however, demonstrated this fact.

Mirrors in a bathroom tiled up to the ceiling have been observed to fog up after a normal hot shower. With doors and windows closed, the mirror remains fogged up to a period of 30 to 60 minutes after the shower.

In a bathroom with mud walls, by contrast, the mirror clears under similar conditions in only 3 to 6 minutes. This is because mud walls absorb humidity from the room when its relative humidity is higher than about 50% and release it later when the air humidity falls below about 50%.

Since humidity in bathrooms with mud walls reduces quickly, fungus growth cannot occur, whereas in tiled bathrooms, the humidity remains high over a longer period due to the sealed surfaces, allowing fungus growth in the joints of the tiles, especially joints grouted with silicone materials.

Modern houses whose principle building material is mud need not have a particular characteristic of outward appearance. They can be traditional or modern, simple or sophisticated, humble or exclusive. There are many ways to build a sustainable farmhouse for the modern traveller. In cold climates, mud as a building material is normally not visible from the outside, since it is covered by the necessary additional thermal insulation and weather protection materials. Interiors, however, can display a variety of mud construction techniques and their manifold applications.

Before getting your hands dirty, consider the 5 Game Changers for a Rural Lifestyle. If you wish to construct a mud house in a unique way, get in touch with us by clicking on the button below.

Dhool Design Studio helps holiday home owners to build unique rentals that is connected with nature to attract more quality guests who are willing to pay premium prices for it.

DHOOL DESIGN STUDIO

Neethi Acharya

Vacation Rental Design Strategist

How to turn your vacant piece of land into a profitable Vacation Rental

How to turn your vacant piece of land into a

DHOOL DESIGN STUDIO

poochtach@dhooldesignstudio.com

+91 9867753996 | +91 9619166758

Neighborhood shopping complex, Sector 4, near state bank of India, Nerul, Navi Mumbai

© 2023 Dhool Design studio. All Rights Reserved